Top Benefits of Using CPQ for Manufacturing Companies

CPQ for manufacturing automates complex product configurations, pricing, and quote generation. A CPQ tool is a software solution that automates and optimizes the configure, price, and quote process specifically for manufacturers. Manufacturing CPQ helps manufacturing companies by automating complex product configurations and streamlining quoting processes, ensuring accuracy and efficiency. This helps manufacturers speed up their sales processes and reduce errors. In this article, we’ll explore the key benefits and real-world applications of CPQ software in the manufacturing industry.

Key Takeaways

- CPQ software streamlines quoting and ordering processes in manufacturing by automating product configurations, pricing, and quote generation.

- The implementation of CPQ reduces quote completion times by over 50%, improves sales efficiency, and enhances customer satisfaction through accurate and timely quotes, including highly accurate price quotes.

- Integrating CPQ with existing ERP and CRM systems enhances data flow and collaboration between sales and engineering teams, driving operational improvements and ensuring accurate pricing.

Understanding CPQ for Manufacturing

CPQ, or configure price quote cpq, stands as a pivotal tool in the arsenal of modern manufacturing companies. This software streamlines the quoting and ordering processes by automating product configuration, pricing, and quote generation, thereby significantly reducing the time and effort involved in these tasks. The implementation of CPQ software in manufacturing not only speeds up sales cycles but also ensures a unified customer experience, marked by improved efficiency and accurate pricing. Various types of manufacturers, including those in the device and furniture sectors, have successfully leveraged CPQ solutions to enhance their sales processes and product quality.

The transformative power of CPQ in manufacturing is rooted in its ability to handle complex product configurations with ease. Automating the configuration process and integrating real-time pricing updates allow manufacturers to offer highly customizable products without compromising on accuracy or efficiency. CPQ software leverages pricing rules to ensure consistent and dynamic pricing for complex product configurations, providing guard rails that support guided selling and customization.

This section delves into how CPQ transforms manufacturing sales processes and the key components that make up effective CPQ software solutions, including pricing solutions that optimize and automate pricing strategies within the CPQ process.

How CPQ Transforms Manufacturing Sales Processes

CPQ software has a profound impact on manufacturing sales processes, primarily by significantly reducing the time taken to generate quotes. CPQ solutions often cut the completion time by more than 50%, allowing for quicker responses to customer inquiries. An advanced cpq solution facilitates real-time quoting and approvals, which are crucial in speeding up sales processes and eliminating bottlenecks that typically slow down the quote-to-cash cycle. CPQ automation streamlines the order process by reducing manual errors and accelerating order completion, ensuring a seamless transition from quote to order. This acceleration not only boosts sales efficiency but also enhances the overall customer experience by providing timely and accurate quotes.

The automation capabilities of CPQ software extend to the configuration process, where product configurators:

- Guide sales teams and customers alike through the selection of options based on their needs and preferences.

- Use rule-based logic to automate the design of customized products, ensuring that only feasible setups are generated.

- Reduce manual errors.

- Streamline the process of configuring complex products.

- Make it easier for sales teams to deliver accurate and tailored quotes quickly.

Moreover, guided selling tools embedded within CPQ systems assist sales representatives in narrowing down product selections based on customer needs and preferences, further enhancing the efficiency of the sales process. By capturing order details and calculating prices accurately based on material costs and pricing structures, CPQ software ensures that manufacturers can respond swiftly and accurately to customer requests, thereby improving lead conversion rates and driving revenue growth.

Key Components of CPQ Software in Manufacturing

The core components of CPQ software in manufacturing are designed to enhance the accuracy and efficiency of the quoting process. A key element is the product configurator, which allows manufacturers to accurately configure complex product options such as:

- Size

- Color

- Capabilities

- Finish

- Material type

Advanced CPQ solutions enable manufacturers to tailor product configurations and quotes to the customer’s specifications, ensuring precise alignment with individual requirements.

This configurator uses predefined rules and business rules to ensure that all configurations are technically feasible and meet customer specifications and technical specifications, thereby reducing errors and enhancing order accuracy while configuring products.

Another critical component is the pricing engine, which automatically calculates pricing based on various factors such as material costs, labor, and logistics, ensuring that quotes are both accurate and competitive. The quote generation feature compiles all product configuration and pricing information to create customized quotes that can be tailored to meet individual customer needs.

Sales teams can further customize the wording or layout of these accurate quote while enabling sales teams to maintain brand standards, enhancing the overall customer experience.

Overcoming Challenges with CPQ Solutions

Traditional quoting methods in manufacturing are often plagued by inefficiencies such as slow response times and inaccuracies, which can lead to lost revenue opportunities and diminished customer satisfaction. CPQ software addresses these challenges by automating the quoting process, reducing lead times, and enhancing pricing accuracy. By automating manual tasks, CPQ allows sales teams to focus more on building relationships with customers, ultimately improving customer experiences and satisfaction.

Moreover, the implementation of CPQ solutions involves ensuring that the system is functional and delivers value early on, which is crucial for improving operational efficiency. Integrating CPQ with supply chain systems can further optimize inventory, costs, and production workflows by enabling better supply chain planning and coordination. This section further explores how CPQ helps manage complex product configurations, streamline pricing structures, and enhance collaboration between sales and engineering teams.

Managing Complex Product Configurations

As the demand for customized products continues to rise, manufacturers face the challenge of managing increasingly complex product configurations. CPQ tools are invaluable in navigating these challenges by providing automated solutions that ensure technical feasibility and accuracy. Rule-based logic in CPQ software permits unlimited customization options while ensuring only valid product configurations are generated.

Constraint-based configuration is another critical feature of CPQ software, which embeds product configuration rules to prevent errors and ensure that all configured products designs are feasible. This not only reduces the likelihood of errors but also ensures that customer orders are accurate and meet their specifications.

An example of this can be seen in the automotive industry, where suppliers have successfully used CPQ software to improve pricing accuracy and streamline the configuration process.

Streamlining Pricing Structures

The core components of CPQ software, including product configurators, pricing engines, and document generators, work together to maintain pricing accuracy and streamline the quoting process. This not only enhances operational efficiency but also improves customer satisfaction by providing accurate and timely quotes. By optimizing production schedules based on real-time demand signals, CPQ can help reduce inventory costs and improve overall efficiency.

Enhancing Collaboration Between Sales and Engineering Teams

Effective collaboration between sales and engineering teams is crucial for ensuring that product configurations and pricing are accurate and aligned with customer needs. CPQ software fosters this collaboration by providing all departments with access to the latest product configurations and pricing information, ensuring that everyone is on the same page. This eliminates manual errors and ensures that all configurations and pricing are accurate and up-to-date.

Automating the product configuration process with CPQ software reduces errors and miscommunications, ensuring seamless handoffs between teams. This not only improves operational efficiency but also enhances customer satisfaction by ensuring that orders are accurate and delivered on time.

Advanced Features of CPQ Software for Manufacturing Industry

Modern CPQ software offers a range of advanced features that significantly enhance sales processes and operational efficiency in the manufacturing industry. These features include product configurators, dynamic pricing algorithms, and advanced analytics, all of which work together to streamline the quoting process, reduce time to order, and improve quote accuracy. Advanced CPQ software can also integrate and optimize multiple sales channels—such as eCommerce, retail stores, and third-party distributors—ensuring consistency and improved partner communication across all points of sale. The integration capabilities of the best cpq software with existing ERP and CRM systems further enhance its effectiveness by ensuring seamless data flow and avoiding duplication.

The following subsections delve into specific advanced features of CPQ software, including dynamic pricing strategies, guided selling tools, and integration capabilities with ERP systems.

Dynamic Pricing Strategies

Dynamic pricing strategies in CPQ software allow manufacturers to adjust quotes based on real-time cost updates from ERP systems, ensuring that pricing is always accurate and competitive. Automated pricing controls play a crucial role in optimizing margins by dynamically adjusting prices in response to changing market conditions.

Dynamic pricing algorithms help manufacturers maximize revenue by aligning pricing strategies with current market conditions and cost structures. This not only enhances pricing accuracy but also provides a significant competitive edge in the market.

Guided Selling Tools

Guided selling tools in CPQ software use intelligent recommendations to help sales reps navigate complex product catalogs effectively, ensuring that they can provide accurate and tailored quotes quickly. These tools leverage customer data to present tailored options based on previous buying behavior and preferences, enhancing decision-making and improving customer satisfaction.

By managing complexity with predefined rules and automation, guided selling tools and a sales automation tool simplify the sales process, making it faster and less prone to errors. This not only improves sales performance but also enhances the overall customer experience by ensuring that customer needs are met accurately and efficiently.

Integration Capabilities with ERP Systems

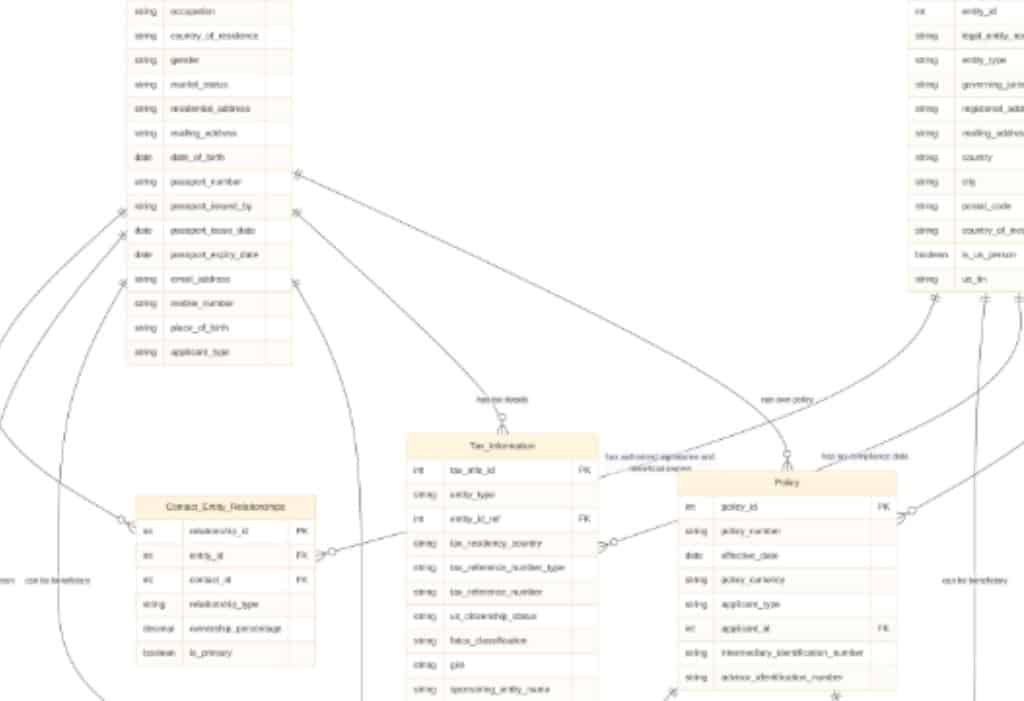

Integrating CPQ with ERP and CRM systems ensures seamless data flow, streamlines workflows, improves accuracy, and avoids duplication. This integration is crucial for maintaining pricing accuracy and providing real-time updates, which are essential for generating accurate and competitive quotes.

A unified ecosystem for data flow created by CPQ software enhances the quote-to-cash cycle, ensuring all departments access up-to-date information and collaborate more effectively. This not only improves operational efficiency but also enhances customer satisfaction by providing accurate and timely quotes.

Unifying CPQ with CRM and ERP

For manufacturing companies, unifying CPQ software with CRM and ERP systems is the ultimate game-changer that transforms sales processes and delivers exceptional customer satisfaction. When these powerful systems work in perfect harmony, manufacturers unlock a seamless flow of information between sales, production, and finance, eliminating data silos and manual entry errors once and for all.

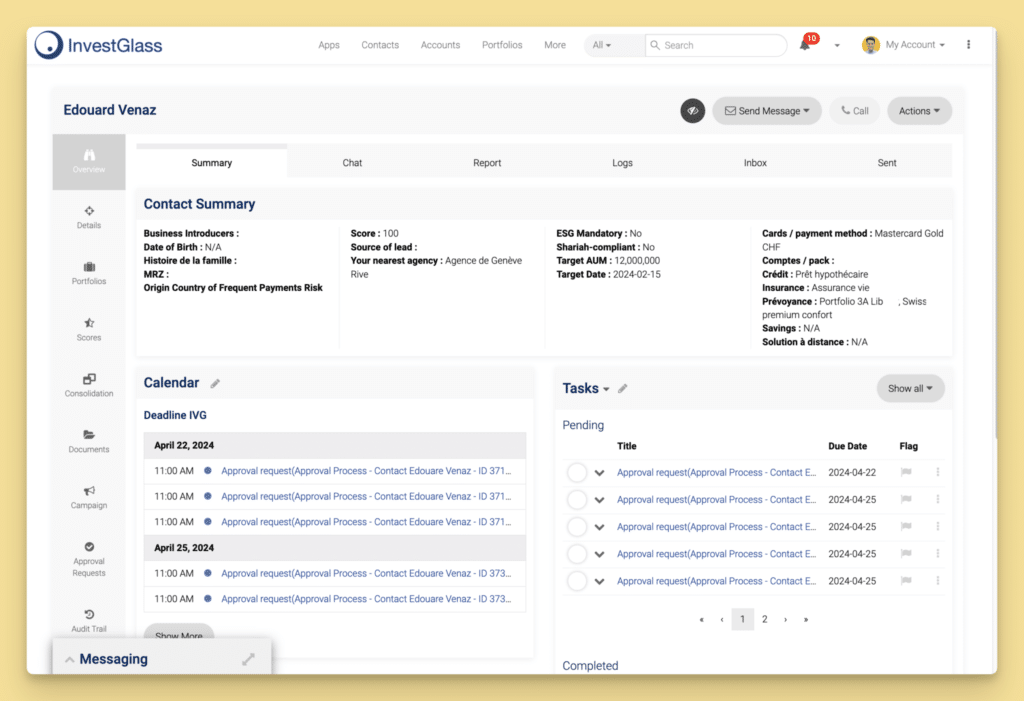

By integrating CPQ with ERP systems, sales teams gain instant access to up-to-date inventory and pricing data in real time, ensuring that every single quote is accurate and reflects current production capabilities and costs. This means customers receive lightning-fast, precise quotes, dramatically reducing delays and building unshakeable trust. Meanwhile, CRM integration empowers sales reps to leverage complete customer history and preferences, enabling highly personalized and responsive quoting that not only meets but exceeds customer expectations.

This unified, powerhouse approach accelerates the quote to cash cycle by automating order processing and creating flawless coordination between sales and production teams. As a result, manufacturers can eliminate errors, optimize production scheduling, and deliver on customer commitments with unwavering reliability. Ultimately, integrating CPQ, CRM, and ERP systems empowers manufacturing companies to achieve superior customer satisfaction, streamline sales processes, and drive operational excellence that sets them apart from the competition.

Manufacturing Software and CPQ

Manufacturing software and CPQ solutions are the game-changing tools your modern manufacturing company needs to streamline sales processes and deliver exceptional customer experiences. Your CPQ software acts as a powerful sales automation engine, empowering your sales reps to quickly capture order details, calculate prices, and communicate complex product requirements to engineering teams with remarkable ease.

By leveraging business rules and customer data, your CPQ software automates the configuration process, ensuring that every quote you deliver is accurate and perfectly tailored to your customer specifications. This doesn’t just reduce the risk of costly errors—it enhances customer satisfaction by providing fast, reliable responses that keep your customers coming back. Your manufacturing software integrated with CPQ solutions helps you manage everything from quotes and bills of material to complex order processing, making it easier for your sales and engineering teams to collaborate seamlessly and deliver on customer needs.

Leading CPQ providers like Salesforce CPQ, Tacton CPQ, and SAP CPQ offer specialized solutions designed specifically for the unique challenges your manufacturing industry faces. These proven platforms help your manufacturing company optimize sales performance, enforce business rules with precision, and deliver accurate quotes that drive revenue growth and improve customer experiences you can count on.

Benefits of Implementing CPQ Software in Manufacturing

Implementing CPQ software in the manufacturing industry offers a multitude of benefits that extend beyond mere automation. These benefits include:

- Enhancement of efficiency in the quoting process, allowing manufacturers to generate accurate quotes faster and with greater precision.

- Quicker turnaround times, which is crucial in an industry where time is often a critical factor.

- Significant reduction in sales cycle durations.

- Enhanced operational scalability, providing a competitive edge in the market through manufacturing software.

Real-world examples illustrate the tangible benefits of CPQ software. For instance, a custom equipment manufacturer reported a substantial reduction in their quoting time, leading to improved workflow and faster sales processes.

Similarly, an automotive supplier experienced improved customer satisfaction through more reliable and timely quotes, demonstrating the positive impact of CPQ on customer experiences. These examples underscore the transformative potential of CPQ software in the manufacturing sector. To fully realize these benefits, it is essential to provide training and resources to both sales and support teams, ensuring everyone is equipped to maximize the value of CPQ implementation.

Accelerating the Quote-to-Cash Process

CPQ software plays a pivotal role in accelerating the quote-to-cash process, which is essential for driving revenue growth and improving cash flow. Reducing quote completion times by more than 50% with CPQ solutions gives manufacturers a significant competitive edge through faster service and quicker deal closures. This acceleration transforms quoting from a process that typically takes days or weeks into one that can be completed in minutes, thereby increasing lead conversion rates and driving revenue growth.

Furthermore, CPQ software manages customer orders effectively from quote creation to delivery and order processing, minimizing delays and allowing sales teams to focus on closing deals. By automating the documentation process, CPQ software ensures that all necessary paperwork is completed quickly and accurately, further speeding up the sales cycle and enhancing the ordering process.

Improving Customer Satisfaction

Improving customer satisfaction is a key benefit of implementing CPQ solutions in the manufacturing industry. By responding to customer inquiries within hours instead of days, CPQ systems enhance the overall customer experience and satisfaction. The ability to provide accurate and tailored quotes quickly leads to better customer experiences and higher satisfaction levels.

Tailored quoting features in cpq solutions tailored meet individual customer needs, enhancing the overall customer experience. Tracking customer feedback regarding quote accuracy and response times can provide valuable insights into customer satisfaction with the CPQ process, enabling manufacturers to continuously improve their personalized solutions.

Reducing Production Costs and Errors

CPQ software significantly reduces production costs and errors through its automation features, which minimize manual input and associated errors. Its benefits include:

- Avoiding ordering errors due to component incompatibility, saving time and money for manufacturers.

- Real-time data integration that allows manufacturers to maintain accurate pricing based on fluctuating costs.

- Ensuring that quotes are both accurate and competitive, thanks to the cpq system.

Pricing accuracy is critical for profitability, especially in an industry where costs can fluctuate frequently. CPQ software improves efficiency and provides accurate delivery times by ensuring that all configurations and accurate prices are up-to-date, helping to avoid pricing errors.

The benefits of improved collaboration due to CPQ software include reducing miscommunications, avoiding rework, and allowing seamless handoffs between teams.

Accurate Quotes and Pricing

Precision quotes and smart pricing are the absolute game-changers for manufacturing powerhouses looking to dominate their markets. CPQ software delivers rock-solid pricing accuracy by unleashing predefined rules and harnessing real-time data streams, completely eliminating those profit-killing pricing blunders that can devastate your margins or shatter customer trust. Your sales warriors can configure products to exact customer specifications, guaranteeing that every single quote captures the true cost and maximum value of your configured solutions.

This level of surgical precision doesn’t just elevate customer satisfaction—it supercharges your sales performance by building unshakeable credibility and rock-solid confidence with your buyers. By consistently delivering spot-on accurate quotes, manufacturing champions can slash the risk of expensive mistakes, accelerate their sales cycles, and fuel explosive revenue growth through improved win rates and unbreakable customer loyalty.

Sales and Revenue Growth

CPQ software is the game-changing catalyst that transforms sales and revenue growth across the manufacturing landscape. By revolutionizing your sales process and empowering teams to configure products with lightning speed and precision, CPQ solutions don’t just help manufacturers close deals—they accelerate business wins and supercharge overall sales efficiency. The power to generate pinpoint-accurate quotes tailored to each customer’s unique specifications means you’re eliminating delays and dramatically increasing your chances of securing that business.

What’s more, CPQ software delivers invaluable intelligence into customer behavior and sales patterns, giving manufacturers the strategic edge to fine-tune their approach and zero in on those high-value opportunities that matter most. The result? Manufacturing companies don’t just improve customer satisfaction—they unlock their sales teams’ full potential and drive the kind of sustained revenue growth that keeps them ahead in today’s competitive marketplace. With CPQ, you’re not just getting software—you’re gaining a trusted partner that helps you scale faster and deliver exceptional customer experiences.

Real-World Use Cases of CPQ in Manufacturing

Several manufacturing companies have experienced significant improvements by implementing CPQ solutions, as evidenced by real-world case studies. These case studies highlight the transformative impact of CPQ software on sales processes, operational efficiency, and customer satisfaction. For instance, a custom equipment manufacturer utilized CPQ software to enhance their sales processes and significantly reduce lead times. Similarly, an automotive supplier employed CPQ to efficiently manage complex product configurations and improve pricing accuracy, resulting in better sales outcomes.

These examples demonstrate how CPQ tools can drive sales efficiency and accuracy in the manufacturing sector. By streamlining the quoting process, managing complex configurations, and ensuring accurate pricing, CPQ software enables manufacturers to respond quickly to customer demands and stay competitive in the market.

Case Study: Custom Equipment Manufacturer

A custom equipment manufacturer faced challenges in generating accurate and timely quotes due to the complexity of their product configurations. By implementing CPQ software, they were able to quickly generate a bill of materials each time a sales rep adjusted a configuration, significantly enhancing the product customization process in sales. This not only improved the efficiency of their sales processes but also reduced lead times, allowing them to respond more quickly to customer inquiries and demands.

The ability to amend the bill of materials in real-time ensured that all configurations were technically feasible and met customer specifications, thereby reducing errors and improving order accuracy. This case study highlights the significant impact that CPQ software can have on manufacturers dealing with complex and mass customization products.

Case Study: Automotive Supplier

An automotive supplier faced challenges with managing intricate product configurations and ensuring pricing accuracy. The implementation of CPQ software enabled them to efficiently manage these complex configurations, leading to enhanced precision in pricing. By using CPQ, the supplier was able to streamline their configuration process and ensure that all quotes were accurate and competitive.

As a result of using CPQ, the accuracy of pricing improved significantly, allowing the supplier to make more competitive offers and enhance customer satisfaction. This case study demonstrates the benefits of CPQ software in managing complex product configurations and improving pricing accuracy in the automotive industry.

Selecting the Right CPQ Solution for Your Business

Selecting the right CPQ solution for your business requires a thorough assessment of your specific needs and challenges. Manufacturers should consider factors such as product complexity, pricing strategies, and sales processes when identifying business requirements for a CPQ solution. Additionally, it is crucial to evaluate the total cost of ownership, return on investment (ROI), customer testimonials, and the vendor’s track record in the manufacturing sector.

By carefully assessing these factors, manufacturers can choose a CPQ solution that effectively addresses their specific challenges and delivers the desired benefits. The following subsections provide a detailed guide on identifying business requirements and evaluating CPQ vendors.

Identifying Business Requirements

Selecting the right CPQ solution starts with:

- Assessing specific needs and challenges, such as product configuration complexity and integration requirements with other business systems.

- Pinpointing specific pain points in current processes to choose a CPQ solution that effectively addresses those challenges.

- Establishing clear, measurable objectives for CPQ implementation to ensure the software meets business expectations and improves operational efficiency.

Key requirements may include integration capabilities, pricing complexity management, and user-friendliness. Seamless integration of CPQ with ERP and CRM systems is crucial for maintaining consistent data and reducing manual entry errors. By assessing these requirements, manufacturers can identify the most suitable CPQ solution for their business.

Evaluating CPQ Vendors

When evaluating CPQ vendors, it is important to consider:

- The total cost of ownership to understand the overall financial impact beyond initial purchase prices.

- Customer testimonials to gain insights into a vendor’s reliability and the effectiveness of their CPQ solution in real-world applications.

- The ROI by analyzing the expected benefits and financial returns generated from the CPQ solution relative to its costs.

Thoroughly evaluating these factors allows manufacturers to select a CPQ vendor that offers a solution tailored to their specific needs and delivers the best value for their investment. This careful evaluation process ensures that the chosen CPQ solution will effectively address the manufacturer’s challenges and drive operational improvements.

CPQ Solution and Implementation

Implementing a CPQ solution is the game-changing investment that manufacturing companies need to supercharge their sales processes and absolutely delight their customers. Your success starts with a razor-sharp evaluation of what your business truly needs—product complexity, current sales workflows, and the specific demands of your customer base. You need a CPQ solution that integrates seamlessly with your existing ERP and CRM systems, ensuring information flows like clockwork across all your departments.

A well-executed CPQ implementation transforms everything—streamlined sales processes, thrilled customers, and explosive revenue growth by empowering your sales teams to deliver lightning-fast, accurate quotes that close deals. Leading CPQ software providers, such as Tacton and Salesforce, offer comprehensive implementation services and rock-solid ongoing support to help manufacturers squeeze every ounce of value from their investment. You don’t just get software—you gain a partner who understands your manufacturing challenges.

By investing in the right CPQ solution and focusing on flawless implementation, manufacturing companies boost sales performance, deliver jaw-dropping customer experiences, and dominate their competitive landscape. Continuous evaluation and optimization of your CPQ process ensures that your business stays ahead of evolving customer expectations and industry demands. With the right CPQ partner, you’re not just keeping up—you’re setting the pace.

Measuring Success with CPQ Implementation

Measuring the success of CPQ implementation is essential for understanding its impact on sales performance and overall business operations. Key performance indicators (KPIs) provide objective metrics to evaluate the effectiveness of CPQ software in manufacturing. Tracking these KPIs helps companies identify areas for improvement and adjust their business logic and usage strategies accordingly.

Regular analysis of current quoting processes and KPIs can lead to improved sales performance outcomes by identifying inefficiencies and optimizing the use of CPQ software. The following subsections discuss the importance of tracking sales performance metrics and assessing customer experience improvements.

Tracking Sales Performance Metrics

Tracking KPIs after CPQ implementation is crucial to measure sales performance, ROI, and operational impact. Key performance indicators to assess sales performance include sales cycle times and overall ROI. Measuring these KPIs can help companies identify areas for adjusting business logic and usage strategies.

Sales cycle times can be shortened by up to 25% through the use of CPQ tools, allowing for quicker deal closures and improved sales performance. By regularly tracking these metrics, manufacturers can ensure that their sales operations CPQ implementation is delivering the desired benefits and driving operational improvements, resulting in faster sales cycles.

Assessing Customer Experience Improvements

Customer satisfaction can be gauged through metrics such as the response time for quotes and the accuracy of the provided information. By tracking these metrics, manufacturers can gain insights into customer experiences and customer relationship management, which enables customers to improve customer satisfaction by identifying areas for improvement.

Regularly assessing customer feedback and response times allows manufacturers to continuously improve their CPQ processes and enhance customer satisfaction. This ongoing evaluation ensures that the CPQ software is meeting customer expectations and delivering a positive customer experience.

Best Practices for Maximizing CPQ Effectiveness

Implementing tailored training programs for different sales roles enhances the effectiveness of CPQ software. Hands-on training with real-world simulations is essential for mastering CPQ software functionalities and ensuring smooth adoption. Effective training is crucial for maximizing the capabilities of CPQ software in manufacturing.

The following subsections discuss best practices for training sales teams and reps, as well as the importance of continuous improvement and updates to maintain the effectiveness of CPQ solutions.

Training Sales Teams and Reps

Training is essential for CPQ software users as it ensures smooth adoption and maximizes user efficiency. CPQ software features intuitive interfaces, built-in product rules, and guided selling features, which help accelerate the onboarding process for new sales representatives. Ongoing support and training are crucial as they help maximize user efficiency during and after CPQ software implementation.

Assessing vendor support and training options is essential for ensuring long-term success with CPQ software. By providing continuous training and support, manufacturers can ensure that their sales teams are well-equipped to use CPQ tools effectively and drive operational improvements.

Continuous Improvement and Updates

Regular updates to CPQ systems are essential for adapting to changing market conditions and maintaining effectiveness. These updates are critical for:

- Maintaining software performance

- Addressing evolving business needs

- Ensuring the accuracy and effectiveness of CPQ solutions through regular system updates and reviews of pricing and configuration rules.

By continuously improving and updating CPQ systems, manufacturers can ensure that their software remains effective and aligned with current market conditions. This ongoing process helps maintain a competitive edge and enhances customer satisfaction by providing up-to-date and accurate information.

Summary

In conclusion, CPQ software stands as a transformative tool for the manufacturing industry, offering significant benefits such as enhanced efficiency, improved customer satisfaction, and reduced production costs and errors. By automating the quoting process and integrating with existing systems, CPQ solutions streamline sales processes, manage complex product configurations, and ensure accurate pricing. Real-world case studies demonstrate the tangible impact of CPQ software on operational efficiency and customer experiences.

The key to maximizing the effectiveness of CPQ software lies in selecting the right solution, providing comprehensive training for sales teams, and continuously updating the system to adapt to changing market conditions. By following these best practices, manufacturers can unlock the full potential of CPQ and drive growth in an increasingly competitive market. Embrace the future of manufacturing sales processes with CPQ software and watch your business thrive.

Frequently Asked Questions

What is CPQ software and how does it benefit manufacturing companies?

CPQ software enhances efficiency and accuracy for manufacturing companies by automating product configuration, pricing, and quote generation. This leads to improved sales processes and a better overall customer experience.

How does CPQ software handle complex product configurations?

CPQ software effectively handles complex product configurations by utilizing rule-based logic and constraint-based systems to ensure technical feasibility and accuracy, thus preventing errors and generating only valid product designs. This automation streamlines the configuration process, resulting in greater efficiency.

What are the key components of CPQ software in manufacturing?

The key components of CPQ software in manufacturing are product configurators, pricing engines, and quote generation features. Together, they enable accurate product configuration, precise price calculations, and the creation of customized quotes.

How does CPQ software improve customer satisfaction?

CPQ software enhances customer satisfaction by delivering accurate, personalized quotes rapidly, which addresses customer needs effectively and results in improved experiences. Ultimately, this efficiency fosters higher satisfaction levels among clients.

What should manufacturers consider when selecting a CPQ solution?

Manufacturers should prioritize product complexity, pricing strategies, and the total cost of ownership when selecting a CPQ solution, ensuring it aligns with their specific needs and delivers a strong return on investment. Evaluating customer testimonials and the vendor’s experience in the manufacturing sector can also guide an informed decision.